In a company where the requirement to stay afloat is the bottom line, you need employees and partners that will help you get there. When machines go down or stop working efficiently, an experienced professional armed with the most effective technology, able to provide service with minimal interference, is the most ideal solution to the problem. One of the best methods to ensure your machinery continues working effectively, fast and long, is vibration analysis. This process involves the monitoring of the pre-determined vibration character of a machine. This allows the operator to distinguish variations in the amplitude, intensity, and frequency of a system to expose any inconsistencies within a machine. This wonderful and accurate process will allow the operator to gain insight into the functionality of the machine while it’s in motion.

Benefits of Vibration Analysis

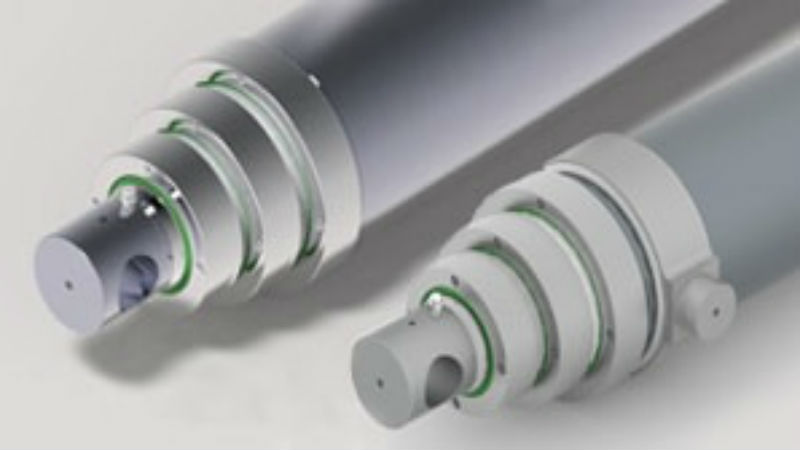

Turning machines, machine centers, and basically any machine using numerous axes of motion to operate will benefit from vibration monitoring. This process can accurately assess the condition and ability to function in certain machines. You can also use this method to find defective parts and inaccurate alignment in the equipment. Using vibration analysis can also help determine the proper repair techniques and maintenance tools needed to preserve the functionality and efficiency of a machine. This technique is extremely accurate and helpful in properly assessing and maintaining the optimal ability for quality production in equipment. Companies that use this method understand the importance of proper alignment to maintain an efficiently operating machine. Laser Precision is one of those companies.

About Laser Precision

Laser Precision offers vibration analysis in Fort Worth Texas. Throughout the years, Laser precision has substantially helped companies, throughout Texas, improve utility cost and the number of product returns, by using their efficient precision alignment tool and calibration technology to properly align machines. Laser Precisions certified technicians are capable of effectively aligning machinery using two main systems, resulting in laser-aligned machines, decreased amount of downtime, ensured accuracy of all machine parts, reduced scrap parts, lengthened overall tool life and increase productivity. Laser Precision will significantly benefit any company using their cutting-edge alignment systems and laser interferometers. The best choice for Vibration Analysis in Fort Worth is Laser Precision.