A belt sander, regardless whether it is handheld or stationary, is an invaluable tool for both the DIY woodworker and the professional shop. No matter the size, belt sanders are great for finishing a board and smoothing off any rough surfaces or edges.

In the professional woodworking world, wide belt sanders are perhaps one of the most common pieces of equipment in the shop. They are used bring material down from its rough size to the design dimension; they prepare the surface of the wood for one or more coatings of finish. These machines are the workhorse of the furniture industry where large wood surfaces are common.

Wide belt sanders are available in many different configurations. A machine that is fitted with numerous sanding heads results in fewer set up changes to achieve the objective, unfortunately it is the multiple heads that most often result in errors, more material is removed than is needed, this of course results in excessive re-work and even scrap. As there are a number of variables that are unique to each machine, it is important that operators are schooled in the proper set-up and test runs of the sander. The three important elements of using wide belt sanders is to remove the correct amount of wood, the surfaces must be level and parallel and the correct abrasive must be used. When these three considerations are applied correctly, the results are optimum.

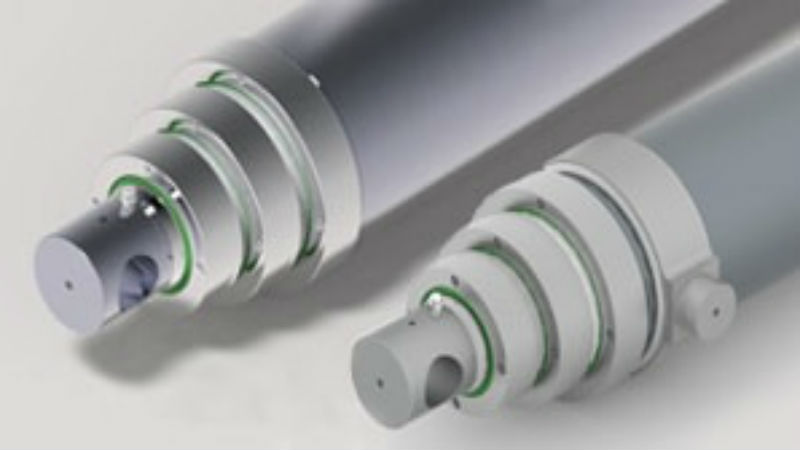

Wide belt sanders must be set-up correctly, there are many considerations. The condition of the platen, feed belt and drums must be good. The operator must know how to set up the rollers and how to determine the correct speed of the sanding heads. The length of the machine bed must be constantly taken into account as it directly controls the length of the work piece.

If the machine is well set-up, half the battle has been won. Perhaps the more important half is the abrasive. It is the abrasive that does the work; the machine is just the power behind it. The abrasive must be run at the correct speed; the scratch depth must be set correctly and it must run across the surface evenly.

The wood type and grain direction must be considered when setting up and employing wide belt sanders.

Allwood Inc are major suppliers of new and used woodworking equipment and supplies. With more than 30 years experience in the business, you can be sure that whether you want wide belt sanders, routers, shapers or any other professional machines, you will find them in stock.