In the world of manufacturing and engineering, the ability to handle large-scale projects efficiently is crucial. Large Capacity Machining represents a pivotal solution in this sector, offering substantial benefits across various industries. This process involves the use of large-scale machinery to fabricate parts that are typically too large for standard machines. Understanding the benefits and uses of this type of machining can help businesses make informed decisions about their manufacturing processes.

What is Large Capacity Machining?

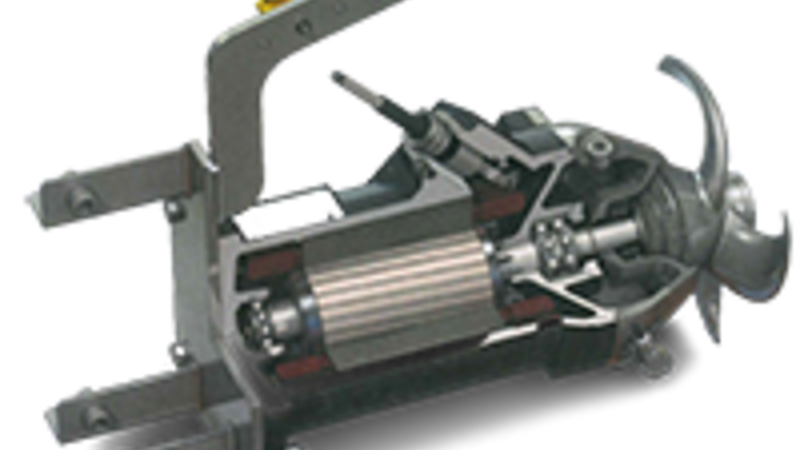

Large capacity machining involves the use of oversized machines, including mills, lathes, and grinders, to handle very large parts or to perform tasks on a larger scale than usual. These machines are designed to maintain precision and accuracy even with extremely large workpieces.

Benefits of Large Capacity Machining

• Increased Efficiency: : Large machines can handle bigger parts, reducing the need for breaking down projects into smaller components. This can significantly cut down on assembly time and increase throughput.

• Enhanced Precision: : Despite their size, large capacity machines are built to deliver highly precise results, which is critical in industries where accuracy is paramount, such as aerospace and defense.

• Versatility: : These machines can work with a variety of materials, from metals to plastics, making them suitable for a wide range of industries.

• Cost-Effectiveness: : By reducing the time and labor needed to produce large parts, these machines can help lower overall production costs.

Common Uses of Large Capacity Machining

• Aerospace: : Manufacturing parts for aircraft, such as fuselage components and wings.

• Shipbuilding: : Creating large ship components like hull sections and deck parts.

• Energy Sector: : Producing large-scale parts for wind turbines, hydroelectric generators, and other energy infrastructure.

• Transportation: : Crafting components for trains and heavy machinery used in construction and mining.

Choosing the Right Machine for Your Needs

Selecting the appropriate large capacity machining equipment involves several considerations:

• Material Compatibility: : Ensure the machine can handle the specific types of materials you need to work with.

• Size Requirements: : Assess the maximum part size the machine can accommodate.

• Precision Levels: : Consider the precision requirements of your projects to choose a machine that meets your needs.

• Cost: : Factor in not only the initial investment but also maintenance and operational costs.

Conclusion

Large capacity machining is an invaluable process for industries requiring the fabrication of large, heavy parts with precision. Its benefits of efficiency, precision, versatility, and cost-effectiveness make it a preferred choice for sectors like aerospace, shipbuilding, and energy. By understanding the capabilities and applications of these machines, businesses can leverage them to enhance their production capabilities and achieve better outcomes. As technology advances, the role of large capacity machining continues to evolve, providing even more opportunities for innovation in manufacturing large-scale components.