Precision forging is a manufacturing process utilizing forging to reduce costs from machining while providing a high-quality, precise component. When selecting metals, companies often choose aluminum. Precision products produced in this way offer certain advantages over other methods and techniques of metal fabrication.

Five Advantages of Aluminum Precision Forging

When it comes to producing components for various industries, precision forging is advantageous on various levels. Aluminum precision forging produces products that reflect the benefits realized from using this method. They include:

- High dimensional accuracy

- Close tolerances and small radii

- Slight draft angles i.e., 0 to 1 degree

- No post-forging machining to finish the product – the only exception being defined functional surfaces

- Cost-effective – Precision forging reduces the need for other processes e.g., machining, therefore cutting down on production time and both labor and machinery costs

Aluminum precision forging is the highest refinement in forging techniques. The process is ideal for high-performance components. The results – aluminum precision products, provide clear evidence of the capabilities and advantages of relying on this system over other options.

The above does not take into consideration what the actual characteristics of aluminum bring to the equation. The weight-strength ratio of aluminum, together with its anti-corrosive characteristics are of considerable importance for industrial applications. The metal’s high fatigue strength, as well as its non-magnetic conductivity, are enhanced or remain unaffected during the forging process.

Aluminum Precision Products

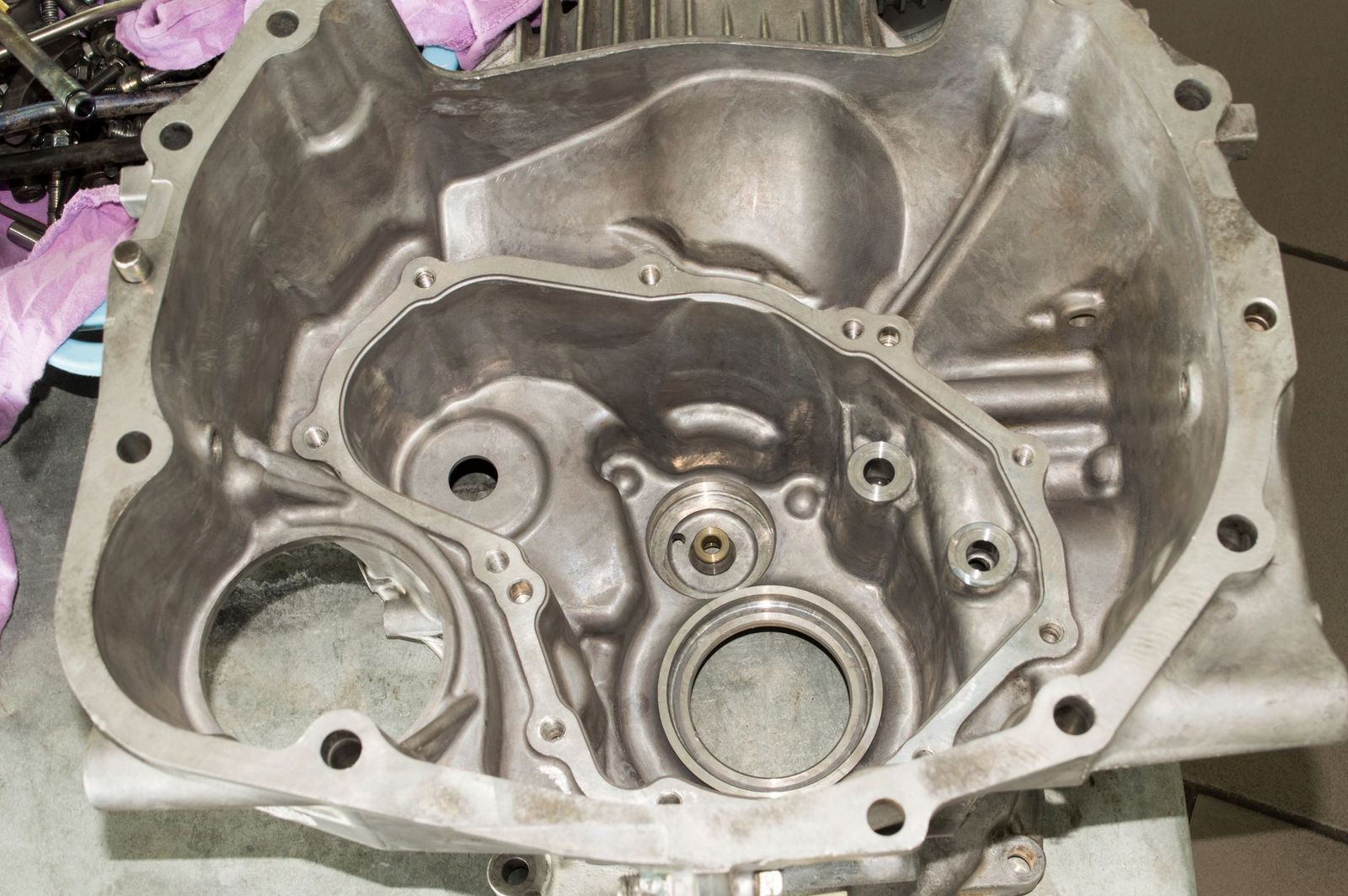

When a company wants to produce a precise part while minimizing the use of machining, precision forging is often the preference. Aluminum precision products provide the tight tolerances and exactitude industries want without the extra cost of finishing. This shortens the production cycle, saving both money and time. In the automotive industry, the results are superior gear wheels, steering pinions, helical gears, and crankshafts. Using aluminum allows companies to have lightweight but highly durable and strong components quickly and easily without sacrificing quality.

If you are looking for a leading provider of high-quality closed die aluminum forging components, contact the team of experienced pros at Business Name. Since 1989, they have been working closely with customers to provide them with Aluminum Precision Products.