It is not uncommon for an OEM to assume that staying to lower tech, manual types of operations to produce parts and components is the most cost-effective option for prototyping as well as production types of orders.

They also assume that using the more sophisticated systems, including an advanced type of production with 5 axis CNC machining service, is going to result in more costly production. However, the benefits of the advanced technology and the advantages it offers can often result in the dual benefits of cost savings and increased speed of order processing and turnaround times.

One Machine – Multiple Options

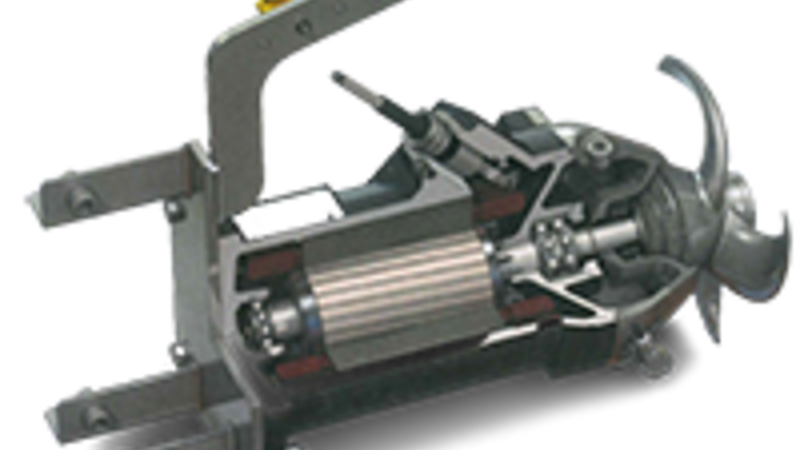

A significant factor in using a 5 axis CNC machining service is the ability to complete multiple complex shaping requirements for both external and internal requirements.

The two additional axes available for the cutting tools to operate around the workpiece creates the option to produce a more complex shape without the need to reposition the workpiece. It also reduces the need to transfer the piece to other equipment or machining systems, both which contribute to time in completing the machining as well as the cost involved.

CNC Precision Control

Another key benefit in reducing waste and maintaining quality control when using 5 axis CNC machining service is the computer control itself. As each piece is designed from the original CAD/CAM or similar program in the system, there is quality control built into the process.

Combining the faster production, the greater precision and the ability to develop complex shapes on one system all contribute to the overall cost-savings possible through the use of the 5 axis CNC machining equipment. The best machine shops can provide this service for prototyping through to production, building in overall cost efficiency for their customers.